News Story

S.K. Gupta and teammates win 2007 'Invention of the Year' physical science award

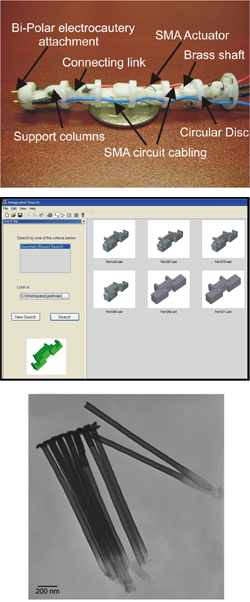

TOP: Minimally invasive neurosurgical intracranial robot. The robot allows neurosurgeons to resect a brain tumor in a minimally invasive manner. It also allows the human patient to actively undergo brain imaging during the operation. The invention is capable of removing intracranial tumors and masses while operating through an extremely narrow corridor in the brain, thus producing minimal disturbance to normal brain tissue. MIDDLE: Geometry Based Search Software (GBSS). GBSS overcomes the shortcomings of existing technology. It has the unique ability to search for objects using 3-dimensional models instead of 2-dimensional images. BOTTOM: Lateral Two-Terminal Nanotube Device and Method for their Formation. This invention enhances the efficiency of energy capture, storage, and delivery. Applications include solar energy capture, energy storage in capacitors and batteries, and integration of capture and storage elements within a thin film process technology to provide high performance energy/power systems at modest cost.

In addition to Gupta, the team includes Associate Professor Jaydev P. Desai (ME); Professor Marc J. Simard, University of Baltimore Department of Neurosurgery; Associate Professor Rao Gullapalli, University of Baltimore Department of Radiology; and mechanical enginering graduate students Nicholas Pappafotis and Wojciech Bejgerowski.

Brain tumors, which occur in 20-40 percent of adult cancer patients, are among the most feared complications of the disease. Despite numerous advances in treatment, the prognosis for these patients is poor, with a median survival of 4-8 months. The primary reasons for the poor survival rate are the lack of good continuous imaging during intracranial surgery and the inability to remove the complete tumor tissue due to its placement and the corresponding space constraints to reach it. Use of magnetic resonance imaging (MRI) during surgery supplements the surgeon’s visual and tactical senses in a way that no other imaging device has achieved, resulting in less trauma to surrounding healthy brain tissue during surgery. To minimize the trauma to surrounding healthy brain tissue, it would be beneficial to operate through a narrow surgical corridor dissected by a neurosurgeon.

The “Minimally Invasive Neurosurgical Intracranial Robot (MINIR)” allows a neurosurgeon to remove brain tumors and other intracranial masses in human patients in a minimally invasive manner while the patient is undergoing brain imaging. The highly dexterous robot can remove intracranial tumors and masses while operating through an extremely narrow corridor in the brain, producing minimal disturbance or damage to normal brain tissues. A U.S. patent application is pending.

Unique features include:

• Sufficiently small size to allow removal of tumors while the patient's brain is imaged.

• Fabrication of materials that are entirely compatible with magnetic resonance imaging.

• A virtual interface between the imaging process (MRI) and the robot that allows the neurosurgeon to conduct the surgery without having to directly visualize the tumor during its removal. The neurosurgeon has direct control of the robot guided by the imaging.

• Ability to manipulate instruments required to destroy tissues, including but not limited to monopolar and bipolar electrocautery, laser, radio-frequency ablator and ultrasonic cavitator

• Ability to manipulate instruments required to remove tissue debris, including irrigation and suction

Gupta is also ‘Information Science’ finalist

Gupta also was a finalist in the information science category for the invention, “Geometry Based Search Software.” Also on his team are research associate Antonio Cardone and research assistant Maxim Schwartz, both from mechanical engineering.

3-Dimensional Computer Aided Drawing (3D CAD) systems have become extremely popular and are frequently used to generate 3D models of parts and assemblies. Companies routinely set up databases of CAD models of their parts and assemblies. Manufacturing companies use these databases to find information that would be useful in estimating things such as manufacturing costs and design reuse. For example, the database of 3D CAD models can be searched for similar parts, and the manufacturing costs of the retrieved parts can be used to estimate the cost of new parts.

Current technology that allows for the searching of 3D CAD databases is inefficient because it often does not yield accurate results. Currently available search software uses projection of 3D CAD model on 2-dimensional planes to create 2D images, which are then compared with 2D images of the existing parts and assemblies. Such a search does not give accurate results. Further, the available search criteria (filters) in conventional software are not customizable by the end user.

The new Geometry Based Search Software (GBSS) overcomes the shortcomings of existing technology. It has the unique ability to search for objects using 3-dimensional models instead of 2-dimensional images. The software can be used to perform quick cost estimation by finding similar designs and examining their costs. GBSS creates a repository of 3D CAD models for different parts, wherein each 3D CAD model is identified by unique signatures. These unique signatures are extracted from an Stereolithography (STL) file of the 3D CAD model and stored in the database. A search query on the database would be translated into these signatures and the database would be searched for the closest match.

GBSS uses intelligent combinations of these signatures to give accurate results. The effect of each signature on the search results can be customized, i.e., a user can specify the weighting of each signature. GBSS provides a quick search and an advanced search, which can be tailored to the user’s specific needs. Overall, GBSS can offer industries more precise and time efficient control over their manufacturing and design processes. A U.S. patent application is pending.

Rubloff is ‘Physical Science’ finalist

A research team led by former ISR director and current Maryland Nanocenter Director Gary Rubloff was a finalist in the Physical Science category for the invention, “Lateral Two-Terminal Nanotube Device and Method for their Formation.”

Also on Rubloff’s team are Assistant Professor Sang Bok Lee, Chemistry and Biochemistry; as well as graduate assistant Parag Banerjee, Center for Automation Research; graduate student Israel Perez, Materials Science and Engineering, and graduate student Erin Robertson, Materials Science and Engineering.

The invention is a method to enhance the efficiency of energy capture, storage, and delivery. Applications include solar energy capture, energy storage in capacitors and batteries, and integration of capture and storage elements within a thin film process technology to provide high performance energy/power systems at modest cost.

The invention introduces a novel approach for forming lateral nanotube energy capture and storage devices that may be configured in arrays. Lateral nanopores are created as anodic aluminum oxide (AAO) nanopores parallel to the surface from an initial aluminum layer. Atomic layer deposition (ALD), electrochemical deposition (ECD) and other processes are used to insert material into the nanopores. Active regions are separately contacted by wiring at opposite ends of the nanostructures. The unique combination of AAO with ALD/ECD enables material to be structured in the nanopores with large active volumes (depletion region for solar cells, capacitor surface area for storage devices) and to achieve the first energy devices from lateral AAO.

The devices are compatible with conventional thin film processing and with multilayers of lateral nanotube devices. For solar energy capture, the multilayer embodiments enable more efficient capture and tuning optical absorption in different layers to different parts of the spectrum. For energy storage, the structures promise high burst power for distributed sensor/actuator systems and other applications. Finally, capture and storage layers may be vertically stacked and combined with control electronics to provide integrated energy systems on a single platform with a common fabrication and process technology. A U.S. patent application is pending.

The awards are presented annually by the University of Maryland Office of Technology Commercialization to honor outstanding inventions and inventors from the previous year. Each year a panel of judges made up of both University of Maryland personnel and industry experts selects one winner from groups of finalists in each of three categories: life science, information science, and physical science. The winners are chosen based on the creativity, novelty, and potential benefit to society of each of the inventions.

Published April 24, 2008